Electrification compatible products

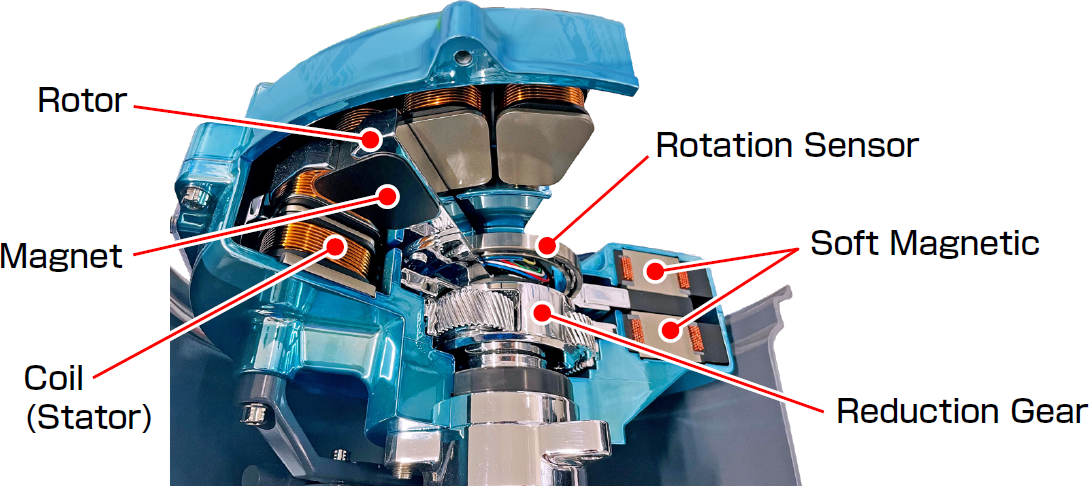

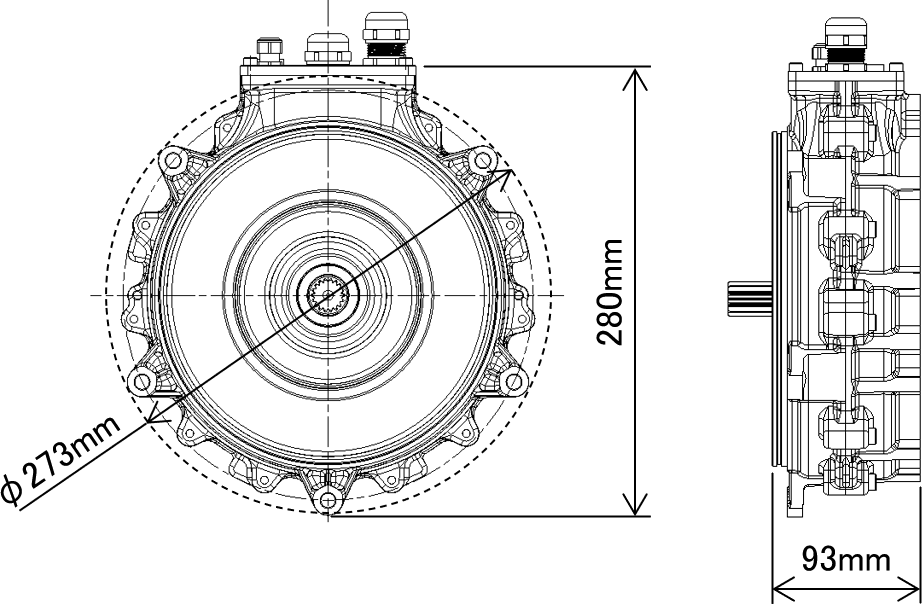

Axial gap motor

We have developed the axial gap motors with flat shapes, rather than general radial gap motors, they have the advantages of space-saving, lightweight, and high efficiency.

The compact and flat shapes are made by concentrated winding and the 3D structured magnetic powder core.

Highest efficiency of 96% with surface magnet topology and non-magnetic rotor components.

Optimization of fractional slots improves torque ripple.

Design proposals for motor output characteristics and mounting geometry are available to meet your requirements.

Motor Specifications

output category |

3.9kW |

2.1kW |

|---|---|---|

weight |

12kg |

12kg |

peak output |

3.9kW |

2.1kW |

magnet |

NdFeB sintered |

Ferrite |

supply voltage |

48Vdc |

48Vdc |

peak current |

150Arms |

150Arms |

rated output (60min) |

2.2kW |

2.1kW |

peak torque (60sec) |

65Nm |

26.5Nm |

rated torque (60min) |

19Nm |

10Nm |

peak speed |

2,300rpm |

5,000rpm |

base speed |

570rpm |

770rpm |

cooling |

Natural air cooling |

|

inverter |

different individual |

|

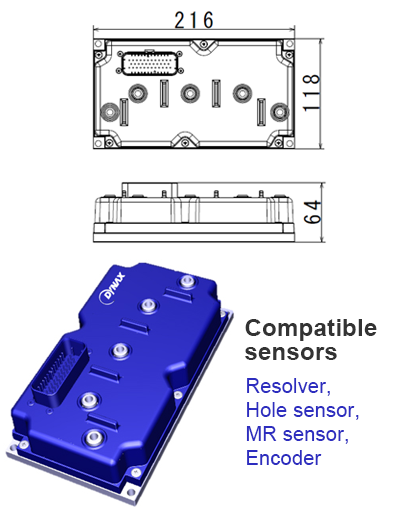

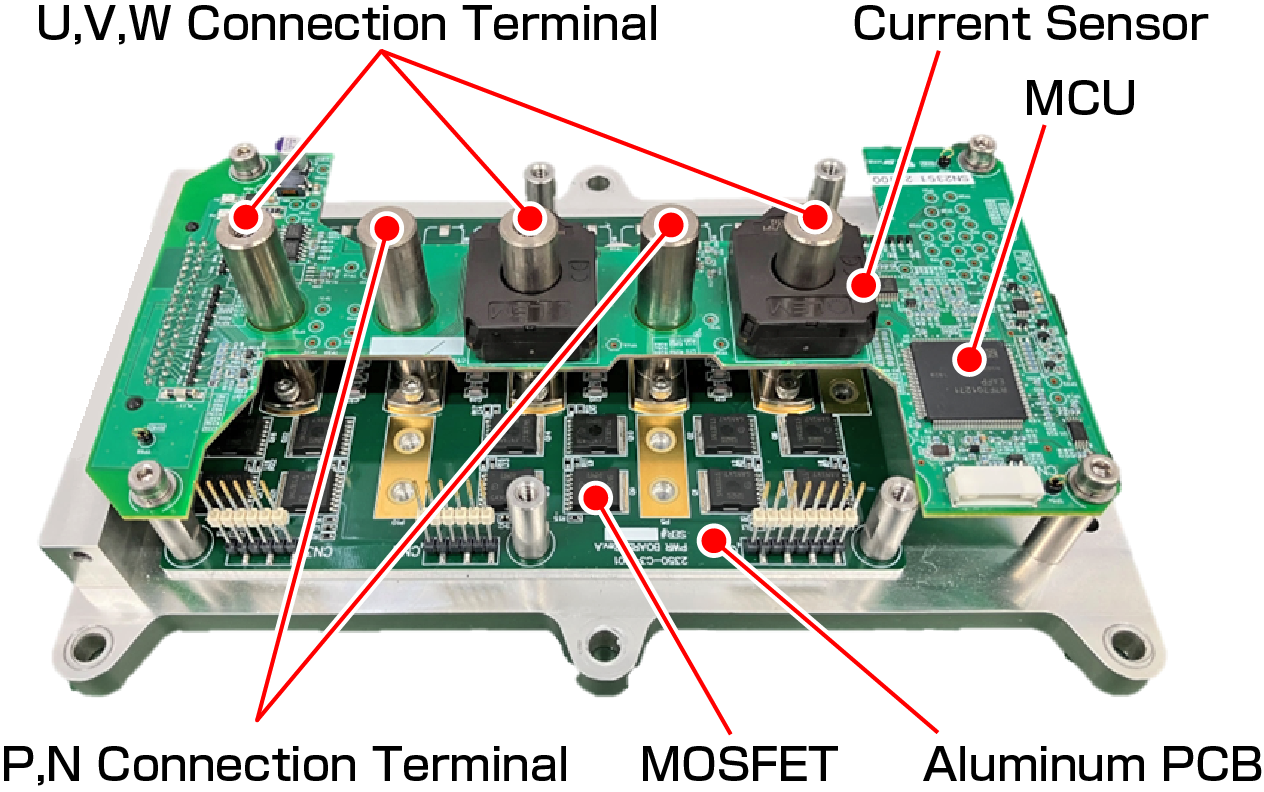

Inverter

By combining with DYNAX motors, we can adjust and propose optimal control

parameters for your application.

Light weight and compact with water proof, dust proof.

Supports a variety of controls and sensors.

Maintenance mode implemented to adjust driving feeling

Specification

Output Category |

Spec |

|---|---|

voltage(V) |

48 |

Max. current (Arms) |

300 (2min) |

Continuous current (Arms) |

150(60min) |

PWM frequency (Hz) |

10k |

Operation temperture (℃) |

-30℃~50℃ |

Cooling method |

Air |

Protection class |

IP65 |

Weight (kg) |

2.0kg |

External interface I/F |

CAN×1 |

Analog Input × 2 |

|

Digital I/O × 4 |

|

High current output × 3 |